Activities

manufacturing

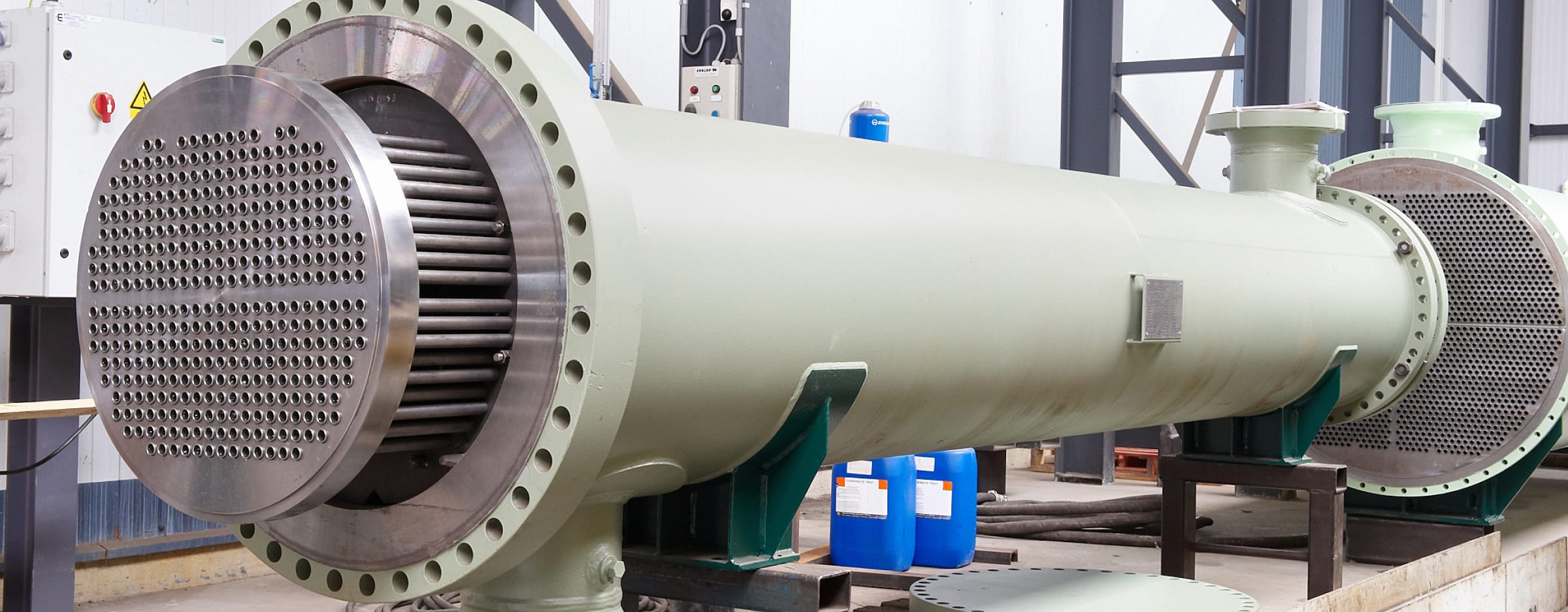

Heat Exchangers

Shell & Tube

- Plain : Welded & Seamless Tubes

- Integral Low Finned Tubes

- All TEMA types

- Double Pipe

- Single- or Multi Tube

- Plain / Finned: circular or longitudinal Tubes

design

Design office equipped to realize all computerized mechanical design according :

- ASME VIII div.1 / ASME VIII div.2

- TEMA

- AD-Merkblätter 2000

- EN-13455

- additional requirement : nozzle loads / fatigue / seismic / …

SOFTWARE:

- ASPEN ( mechanical design of Shell- & tube Exchangers )

- Nozzle pro

- Bentley AutoPIPE Vessel

CAD / CAM workstations generate all general:

- arrangement & detail drawings

- cutting & machining parameters

maintenance

A stock of current tube sizes and a good relationship with the major tube mills permits us to guarantee short delivery periods and a 24h service – 7 days a week

testing

Non-Destructive Test Facilities:

- Hydrostatic & Pneumatic

- Magnetic Particle

- Liquid Penetrant ( dye-check )

- Ultrasonic ( UT + PA + TOFD )

- Hardness / Impact Test

- Positive Material Identification

- Radiographic

- Helium Leak Test

- Feritscope

materials

- Stainless Steel 300 & 400 grades

- Cu Ni alloys + Brass ( Admiralty / Naval / Alu Bronze )

- High Nickel alloys

- Carbon- & Low Carbon Steels / H.I.C. resistant steels

- Clad Metals ( Rolled / Explosion / Weld overlay )

- Duplex, Super-duplex, Hyper-duplex

- Titanium